Participants will learn and be prepared to practice process improvement methods including: process mapping, 5S workplace organization, identification and elimination of waste, error-proofing, standardization of work, and process verification.

This course will be held virtually on August 27, 2024, from 9:00am to 4:00pm. Capacity is limited to 22 people.

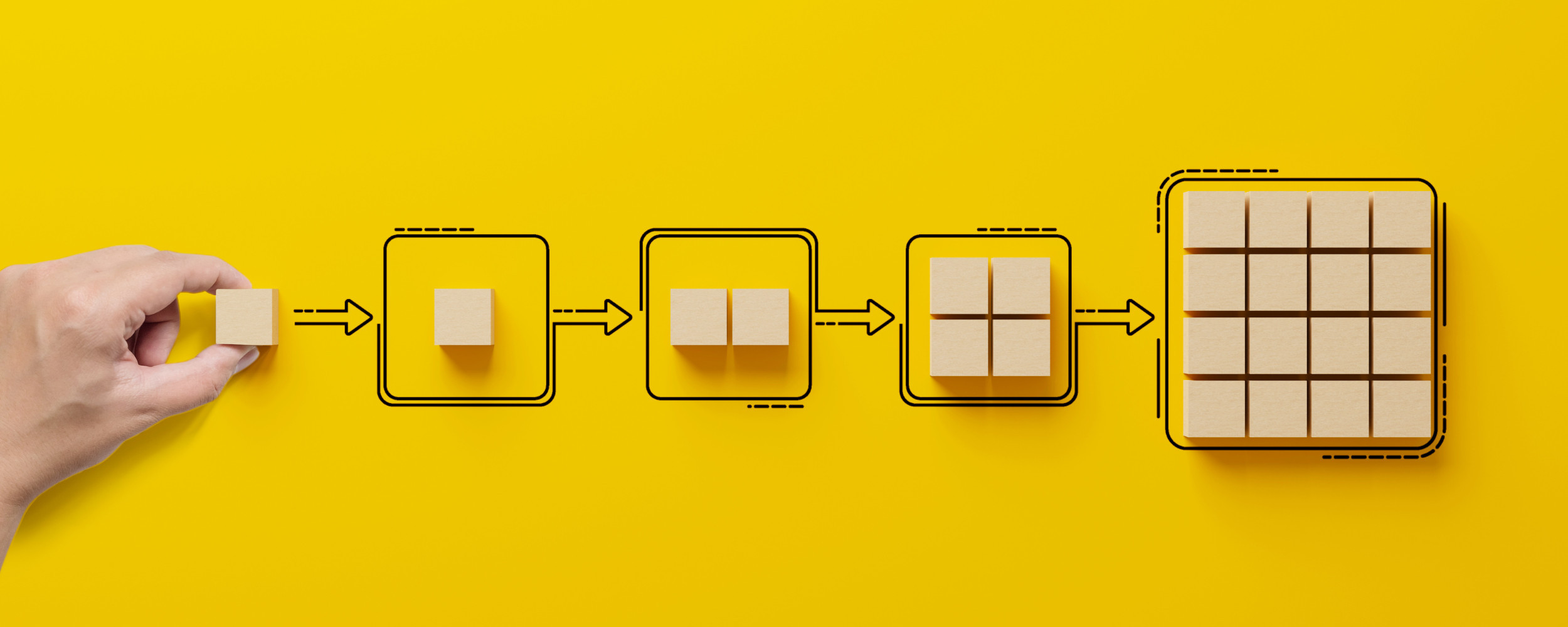

All organizations are continually under pressure to improve outcomes and do more with less – less resources, money, and effort. This live virtual training engages participants into the why, what, and how of process improvement. This training is suitable for those with no or little prior process improvement exposure, since it provides straightforward planning steps and easy to apply tools and methods, including key tools used in Lean initiatives.

Application of the methods learned could be applied to any function or activity that has repeatable steps or work effort. Resulting improvements might include: process simplification, task automation, elimination of paper, digital workflow, improved job instructions, and more.

Upon completion of this course, the learner will be able to:

- Understand the importance and value of continuous improvement

- Frame process improvement initiatives, including the scope, methods, and desired outcomes

- Work with people close to the existing process and highlight recommendations to improve results and reduce effort

- Begin practice with fundamental tools for process improvement including: process mapping, 5S, identification of waste, and standardization of work

- Integrate tools learned into initiatives related to work instructions, problem solving, and continuous improvement

This course would be beneficial to all individuals.

Point Value: 5